Our engineering services are well-renowned for providing exceptional quality, ensuring that every project we undertake meets the highest standards of excellence and innovation

RESEARCH AND DEVELOPMENT

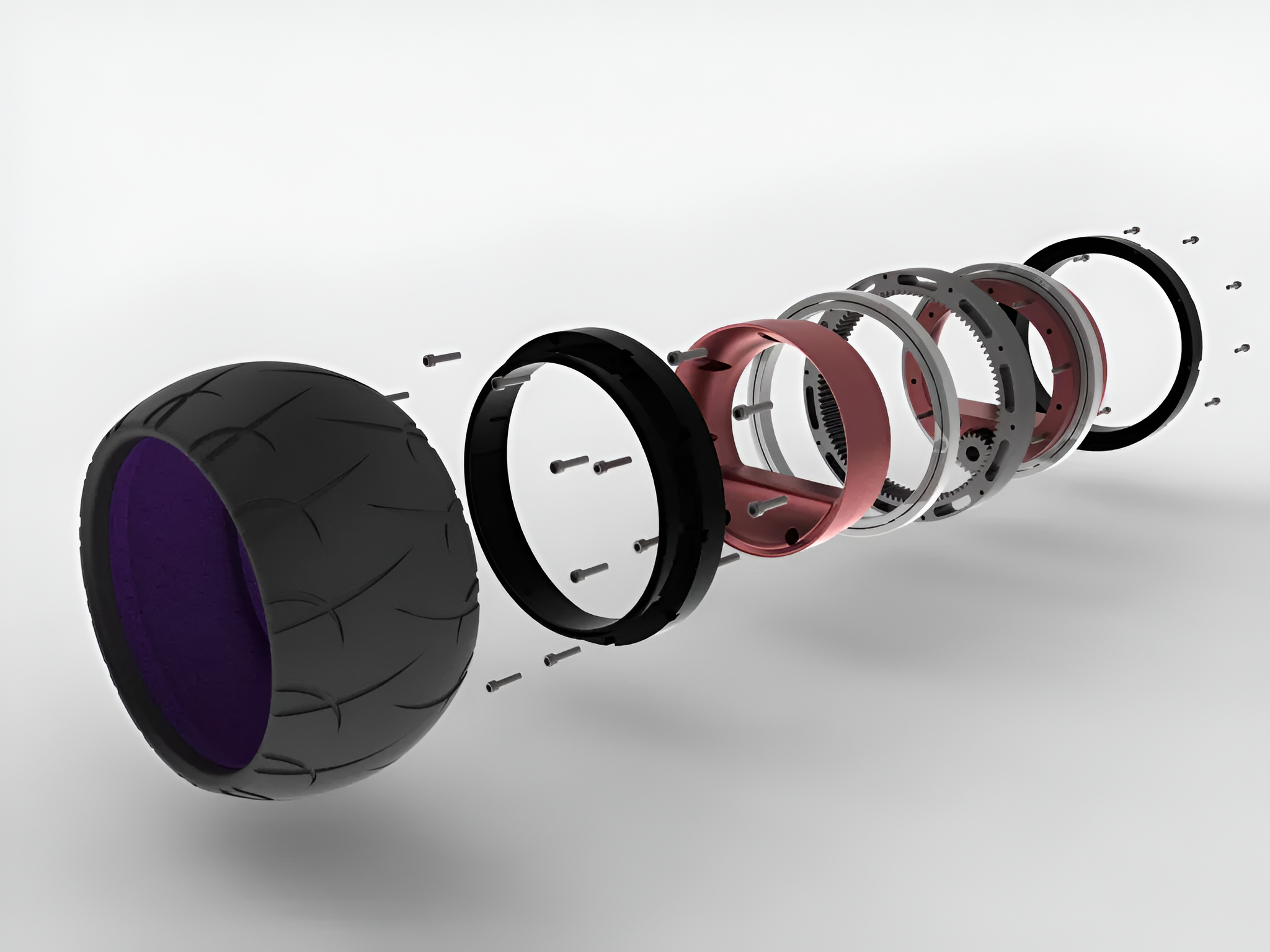

Mega Engineering Vehicle has in depth knowledge in the tooling and engineering of metal parts production. Whether a requirement involves standard overview of capabilities, on hand, turret tooling, and modular tooling or more elaborate dies (such as compound, deep draw, or progressive).

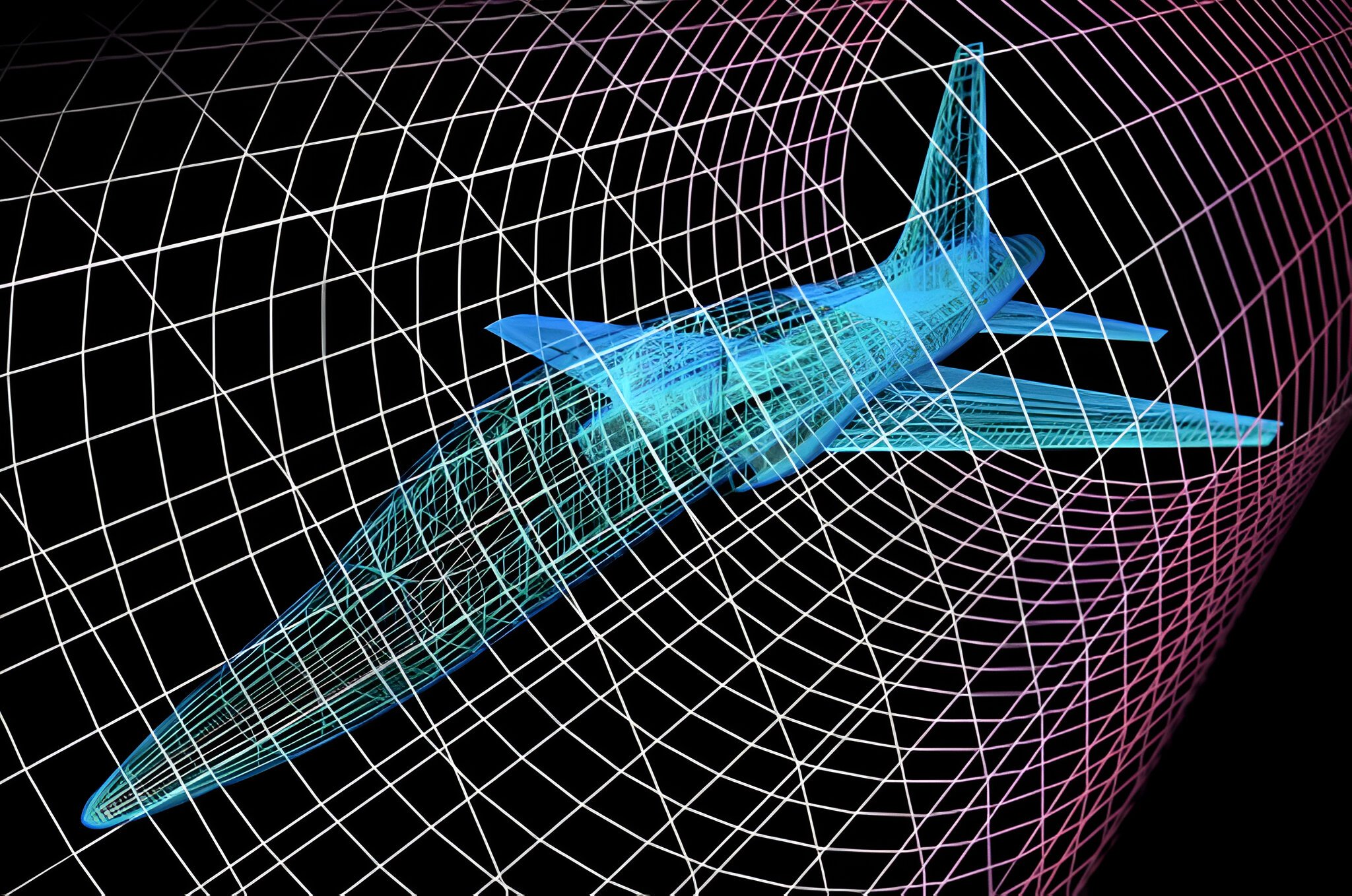

Mega has the most modern equipment and the skilled tradesmen to handle the precision and volume necessary to meet customer deadlines. We use a variety of CAD programs that can communicate directly with our customers, along with computer controlled machining centers and Wire EDM technology.

-

Custom Metal Stamping

Mega Engineering Vehicle can deliver, press tonnage ranges from one-ton hydraulic units to 500 ton automatic presses and the ability to work with nearly any metal material, Mega can provide an unusually wide variety of stamped metal products.

Precision Fabrication

Mega Engineering Vehicle is capable of prototyping and fabricating precision, light gauge metal components and assemblies. We have complete, state of the art production fabricating operations including the most up to date CNC / Turret presses, lasers, forming, bending, rolling, welding, hardware installation and assembly equipment.

CNC Machining

Mega Engineering Vehicle specializes in CNC machining parts and prototypes for OEM products and assemblies. We offer state-of-the-art CNC machining services and expert design support from concept to completion.

System Management

Our continued growth is assisted by our overall corporate commitment to progressive and fully integrated computer systems. Our dedication to technology is evident throughout every area of the business.

*Fully integrated CNC milling centers and Wire EDM’s programming utilizing Striker and MasterCam software.

*Computer controlled SPC Quality Control System.

*Fully integrated Manufacturing and Accounting software

*On-line integrated Bar Coding

*Computerized Preventative Maintenance System.

*Design capabilities using SolidWorks, AutoCAD, Inventor, and Quick Strip

Nesting software

EV Technology

EV Technology with an important goal for electric vehicles is overcoming the disparity between their costs of development, production, and operation, with respect to those of equivalent internal combustion engine vehicles (ICEVs). As of 2013, electric cars are significantly more expensive than conventional internal combustion engine vehicles and hybrid electric vehicles due to the additional cost of their lithium-ion battery pack. However, battery prices are coming down with mass production and are expected to drop further.

-

The cost of charging the battery depends on the price paid per kWh of electricity – which varies with location. As of November 2012, a Nissan Leaf driving 500 mi (800 km) per week is estimated to cost US$600 per year in charging costs in Illinois, U.S.The EV1 energy use was about 11 kW·h/100 km (0.40 MJ/km; 0.18 kW·h/mi). The 2011/12 Nissan Leaf uses 21.25 kW·h/100 km (0.765 MJ/km; 0.3420 kW·h/mi) according to the US Environmental Protection Agency. These differences reflect the different design and utility targets for the vehicles, and the varying testing standards. The energy use greatly depends on the driving conditions and driving style. Nissan estimates that the Leaf’s 5-year operating cost will be US$1,800 versus US$6,000 for a gasoline car in the US According to Nissan, the operating cost of the Leaf in the UK is 1.75 pence per mile (1.09p per km) when charging at an off-peak electricity rate, while a conventional petrol-powered car costs more than 10 pence per mile (6.25p per km). These estimates are based on a national average of British Petrol Economy 7 rates as of January 2012, and assumed 7 hours of charging overnight at the night rate and one hour in the daytime charged at the Tier-2 daytime rate.

-

The following table compares out-of-pocket fuel costs estimated by the U.S. Environmental Protection Agency according to its official ratings for fuel economy (miles per gallon gasoline equivalent in the case of plug-in electric vehicles) for series production all-electric passenger vehicles rated by the EPA as of October 2014, versus EPA rated most fuel efficient plug-in hybrid with long distance range (Chevrolet Volt), gasoline-electric hybrid car (Toyota Prius third generation), and EPA’s average new 2013/14 vehicle, which has a fuel economy of 23 mpg-US (10 L/100 km; 28 mpg-imp).

-

EV Technology with Electric cars have several benefits over conventional internal combustion engine automobiles, including a significant reduction of local air pollution, as they have no tailpipe, and therefore do not emit harmful tailpipe pollutants from the onboard source of power at the point of operation; reduced greenhouse gas emissions from the onboard source of power, depending on the fuel used for electricity generation to charge the batteries. Electric vehicles generally, compared to gasoline vehicles show significant reductions in overall well-wheel global carbon emissions due to the highly carbon intensive production in mining, pumping, refining, transportation and the efficiencies obtained with gasoline.

ELECTRIC AMBULANCE

ELECTRIC TAXI

ELECTIFYING FLEET

ELECTRIC WASTE TRUCK

ELECTRIC POSTAL TRUCK

ELECTRIC SHERIFF VEHICLE

ELECTRIC CRANE

PRODUCTION

There have been many disagreements about what qualifies as a production or modified car in motorsports, even within the Fédération Internationale de l’Automobile (FIA). The rules, written in 1955, outline specific requirements for a certain number of models to be produced within a year to be considered "production," but enforcing these rules is challenging. For example, the 1968 FIA rules stated that sports cars had to have at least 25 identical cars produced in a year for normal sale. However, the FIA allows some modifications from the original. The Utah Salt Flats Racing Association, focused on vehicle speed, has its own definition of a vehicle, allowing significant modifications over the original. In 2006, a Pontiac TransAm was classified as the fastest model with a top speed of over 297 mph. Tests of the same car from the manufacturer did not come close to this speed, indicating discrepancies in motor vehicle production definitions. This information is based on data from 2015 and earlier. The working memory also contains explicit control structure data. For example, when a monkey holds the suspended object, the goal status is set to "satisfied," and the production rule can no longer apply as the first condition fails.